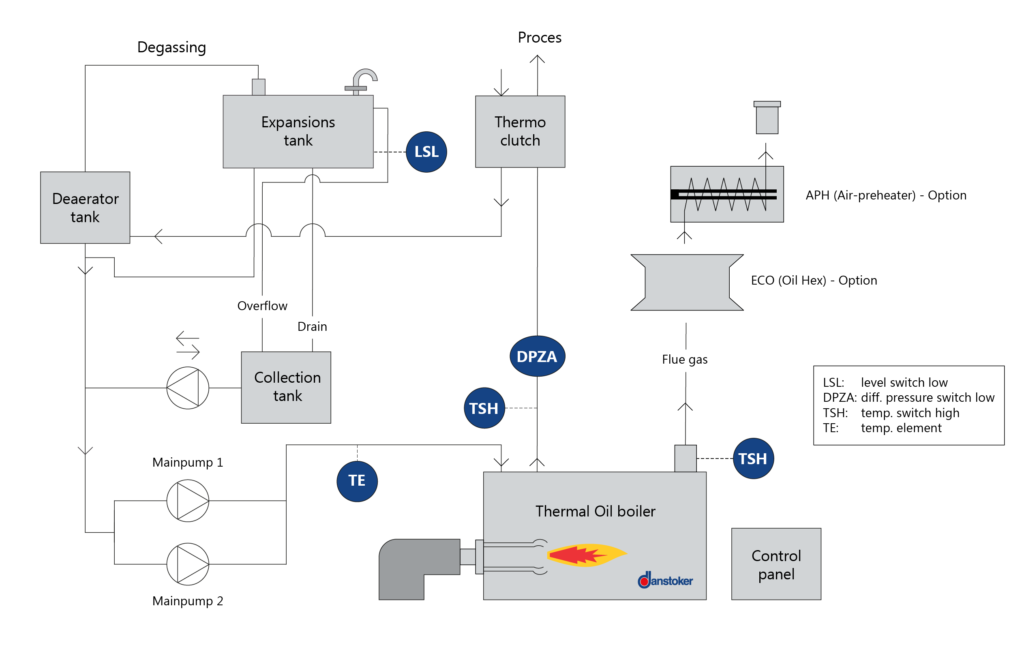

Ancillary equipment for thermal oil boilers

Danstoker designs, builds and supplies complete thermal oil plants composed of several different components:

Expansion tank (ET)

ET is made as a horizontal tank and must always be placed 2 m above the highest point of the thermal oil system.

Design data:

- Desing norm: EN 13445-3:2009

- Design pressure: 0,5 bar(g)

- Max. temp.: 300°C

- Min temp.: 20°C

- Pressure test: 2 bar(g)

- Media: Thermal Oil (mineral oil)

- Plate thickness: 4-6 mm

- Plate material: S 235 JR

- Supplied as standard with manhole and without N2 dosing. Can also be ordered without manhole or with N2 dosage.

N2 dosing at hot oil temperature ≥ 250 °C.

Collection tank (CT)

CT is performed as a horizontal tank and is placed under the expansion tank (ET), where it is connected to the thermal oil system on the return line before the circulation pump(s). Overflow and drains from ET are connected at the top of the CT. Similarly, the CT vent pipe is passed up into the ET.

Design data:

- Desing norm: EN 13445-3:2009

- Design pressure: 0,5 bar(g)

- Max. temp.: 350°C

- Min temp.: 20°C

- Pressure test: 2 bar(g)

- Media: Thermal oil (mineral oil)

- Plate thickness: 4-6 mm

- Plate material: S 235 JR

Delivered as standard without manhole. Can be ordered with manhole.

A separate drain and fill pump is connected between the CT and the thermal oil system.

Deareator tank (DT)

DT is made as a vertical tank and is placed under the expansion tank (ET), where it is connected to the thermal oil system on the return line.

The Tangential thermal oil entry in the deaerator ensures optimal oxidation.

Design data:

- Desing norm: EN 13445-3:2009

- Design pressure: 0,5 bar(g)

- Max. temp.: 300°C

- Min temp.: 20°C

- Pressure test: 2 bar(g)

- Media: Thermal oil (mineral oil)

- Plate thickness: 4-6 mm

- Plate material: S 235 JR

Thermo clutch (TC)

TC is a hydraulic Thermo clutch. In practice, TC provides independency of flow requirement for the heater, which enables a standardization of units for different capacitys. This technology ensures better boiler performance, lower energy consumption and optimized pump sizes.

Design data:

- Desing norm: EN 13445-3:2009

- Design pressure: 10 bar(g)

- Max. temp.: 300°C

- Min temp.: 20°C

- Pressure test: 17 bar(g)

- Media: Thermal oil (mineral oil)

- Plate thickness: 4-6 mm

- Plate material: S 235 JR

Air-preheater (APH)

APH comes with a non-corrosive air pre-heater with a hybrid cross and counter flow design that has been validated with extensive CFD analysis.

Modular APH helps to maintain effeciency even under part load conditions.

System efficiency and NOx emmisions are opposing factors that are taken into account when designing the APH.

Design data:

- Design pressure: 0,4 bar(g)

- Max. temp. flue gas: 400°C

- Max. temp. air out: 150°C

- Media: Flue gas to air

Burner and control panel

Danstoker supplies N-gas, oil or combi- burners for the entire series of our Thermal Oil Boilers (TOB).

Emission and efficiency requirements are crucial for the choice of burner type.

The control panel can either be manufactured as a simple mechanical control unit or optionally with a Siemens PLC.

The safety equipment on the TOB is also integrated in the control panel, which ensures simple and safe operation.

Contact Danstoker with the required data for pricing information.