Electric boilers

The global surplus electricity production from solar and wind energy offers financial benefits when supplementing the heating supply with electric boilers in district heating plants and industrial applications.

Reduce reliance on fossil fuels – Quite often, district heating plants can substitute the use of fossil fuels by leaving it instead to an electric boiler to generate heat for the plant’s accumulation tank when the price of electricity is low. This implies a more environmentally compatible operation and reduced vulnerability to energy price fluctuations.

Industrial companies have similar opportunities of supplementing or replacing hot water, high-temperature hot water and steam boilers with electric boilers. Analyses of the costs and benefits involved have demonstrated that electric boilers are extremely competitive and will improve the company’s CO2 accounts.

High efficiency – The conversion of electricity to heat is very efficient with an absolute minimal loss. This results in lower overall costs and thereby a higher degree of cost-effectiveness over time.

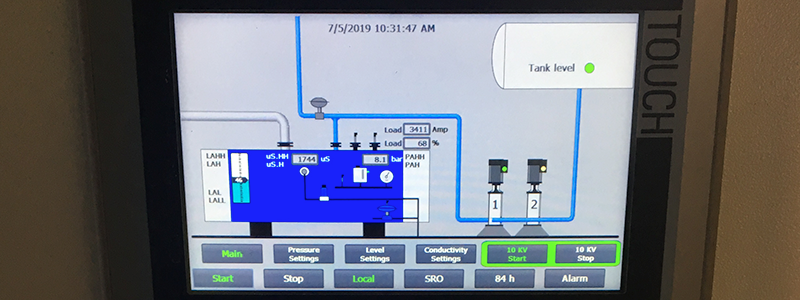

Flexibility – Compared to other solutions, an electrical boiler has very little ramp-up time and can be engaged on very little notice.

Less Maintenance – Electric boilers feature a robust design and a wide range of regulation. In terms of installation, operation and maintenance alike, they are usually more economical than conventional boilers, as no chimney, nor mechanical wearing parts are needed.

Distinction is made between two types of electric boilers:

- Low-voltage boilers

- High-voltage boilers

Danstoker manufactures the low-voltage boiler type.

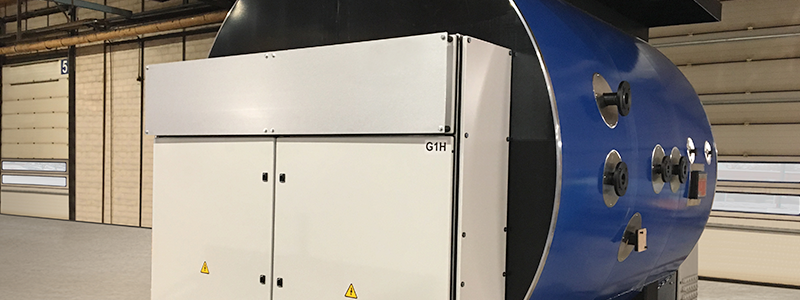

Control cabinet

Power cabinet

Please contact us for further information

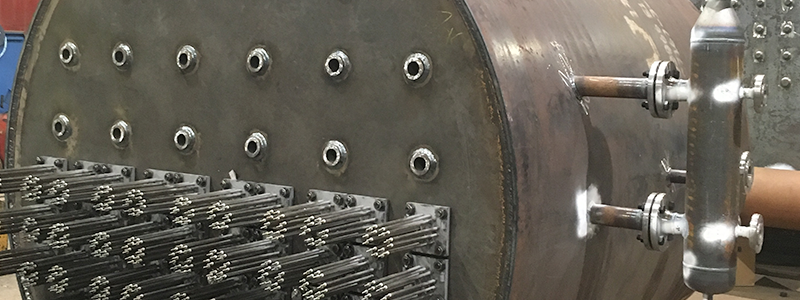

Low voltage element electric boiler

Type: Low or high pressure hot water or steam boiler.

Supply: Electricity (3 x 400 V eller 3 x 690 V)

Steam rating: 600 – 8.400 kg/h ( 3 x 690 V). 600 – 5.500 kg/h (3 x 400 V)

Capacity: 400 – 5.500 kW (3 x 690 V). 400 – 3.600 kW (3 x 400 V)

Pressure: LTHW: 6 barg, HTHW: 10 barg, Steam: 13 barg